ASTM A269 TP304/304L/TP316/316L/316Ti Chemical Injection Line

SSMMCT04

Material: 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635; 310/310S/310H,1.4845;

Get Quote

TP316L / S31603 Stainless Steel Welded Super Long Multi-core Coiled Tube For Marine

Mtsco' s multi-core tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L. The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification and protection purposes each individual tube is PVC sheathed in a different color. The extruded outer sheath is made of oil and seawater resistant, weatherproof, flame retardant, corrosion and acid resistant PVC. The multi-core tube (outer sheath) is continuously marked at every one meter throughout the entire length for easy installation. Heat shrinkable products provide complete water sealing, abrasion and corrosion protection under all conditions.

Chemical Composition

| C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti | |

| TP304/1.4301 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/1.4541 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/1.4449 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 | |

| TP347H/1.4912 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/1.4833 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/1.4845 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | 0.75 |

Where the coiled tubing used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

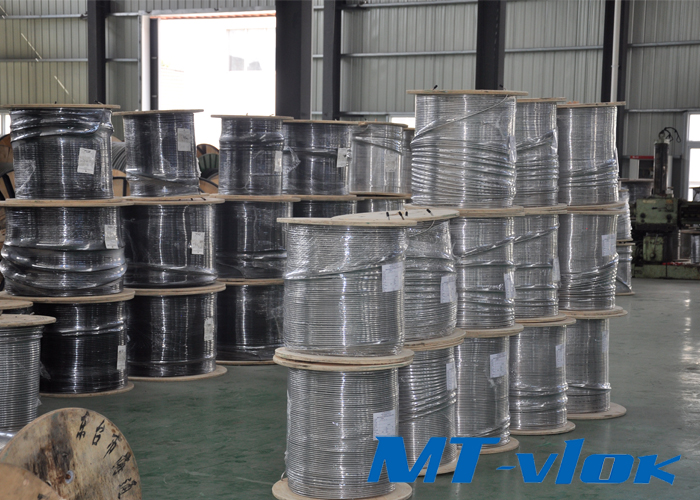

MTSCO is a leading manufacturer who is specialized in seamless coiled tubing produce . Stainless steel seamless coiled tubing final surface is bright annealed. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. They are very popular in military, semiconductor, pharmaceutical biotechnology, precision instruments, hydraulic parts, chemicals industry, boilers and heat exchangers, aerospace industry, automotive industry, electronics, petroleum exploration, precision machinery, rail transportation, shipbuilding plants, air-conditioning industry, solar industry, water heater industry etc. They can be used in many others industries also .

| Ordering code number | Tube size (O.D x Thickness x Core) | Overall Diameter (.mm) | Sheath Thickness (.mm) | Bundle Weight (kg/M) | Max Pressure (Bar) |

| HTD-1 | 6×1.0×1 | 8 | 1.0 | 0.15 |

Working:180Bar

Test:270Bar |

| HTD-2 | 6×1.0×2 | 20 | 2.0 | 0.60 | |

| HTD-3 | 6×1.0×3 | 21 | 2.0 | 0.75 | |

| HTD-4 | 6×1.0×4 | 24 | 2.0 | 0.82 | |

| HTD-5 | 6×1.0×5 | 25 | 2.0 | 0.90 | |

| HTD-6 | 6×1.0×6 | 27 | 2.0 | 1.04 | |

| HTD-7 | 6×1.0×7 | 27 | 2.0 | 1.15 | |

| HTD-8 | 6×1.0×8 | 32 | 2.2 | 1.40 | |

| HTD-9 | 8×1.0×1 | 10 | 1.0 | 0.28 | |

| HTD-10 | 8×1.0×2 | 24 | 1.8 | 0.89 | |

| HTD-11 | 8×1.0×3 | 26 | 2.0 | 1.12 | |

| HTD-12 | 8×1.0×4 | 28 | 2.0 | 1.33 | |

| HTD-13 | 8×1.0×5 | 31 | 2.0 | 1.67 | |

| HTD-14 | 8×1.0×6 | 34 | 2.0 | 2.00 | |

| HTD-15 | 8×1.0×7 | 34 | 2.0 | 2.15 | |

| HTD-16 | 8×1.0×8 | 40 | 2.2 | 2.60 | |

| HTD-17 | 10×1.0×1 | 13 | 1.0 | 0.34 | |

| HTD-18 | 10×1.0×2 | 28 | 1.8 | 1.18 | |

| HTD-19 | 10×1.0×3 | 31 | 2.0 | 1.60 | |

| HTD-20 | 10×1.0×4 | 34 | 2.0 | 1.97 | |

| HTD-21 | 10×1.0×5 | 37 | 2.0 | 2.20 | |

| HTD-22 | 10×1.0×6 | 40 | 2.0 | 2.40 | |

| HTD-23 | 10×1.0×7 | 40 | 2.0 | 2.52 | |

| HTD-24 | 10×1.0×8 | 48 | 2.5 | 3.20 | |

| HTD-25 | 12×1.0×1 | 14 | 1.0 | 0.41 | |

| HTD-26 | 12×1.0×2 | 34 | 2.0 | 1.35 | |

| HTD-27 | 12×1.0×3 | 36 | 2.0 | 1.96 | |

| HTD-28 | 12×1.0×4 | 39 | 2.0 | 2.37 | |

| HTD-29 | 12×1.0×5 | 43 | 2.0 | 2.70 | |

| HTD-30 | 12×1.0×6 | 47 | 2.0 | 3.00 | |

| HTD-31 | 12×1.0×7 | 47 | 2.0 | 3.14 | |

| HTD-32 | 12×1.0×8 | 55 | 2.5 | 3.90 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Encapsulated Tube

1/4 UNS N06625 Oilfield Encapsulated Control Line 3lines With Flat Pack

MTSCO has been supplying industrial tubing to the oil and gas industry for more than a decade. In recent years, we have continued to make breakthroughs in the field of coiled tubing, downhole control lines, and chemical injection control lines. Our coiled tubing has been successfully used in certain......

TP316 / 316L ASTM A269 Stainless Steel Welded Multi-core Coilded Tube For Fuild Industry

The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification and protection purposes each individual tube is PVC sheathed in a different color. The extruded outer sheath is made of oil and seawater resistant, weatherp......ASTM B704 UNS N08825 Oilfield Welded Inhibitor Supply Line With PVDF Encapsulation

An increasing number of projects in the oil service industry require the use of continuous lengths of stainless steel control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語