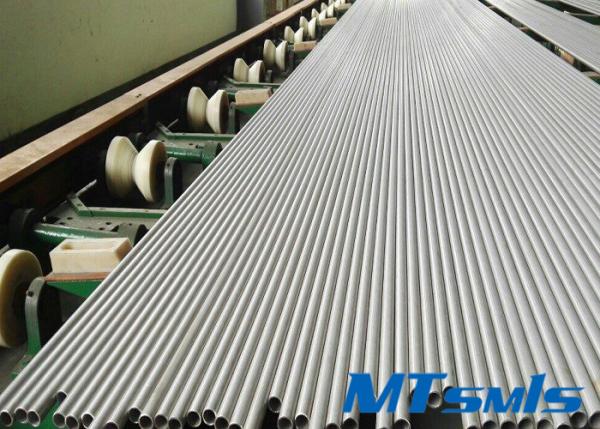

TP304L 25.4*2.11mm U Bend Stainless Steel Heat Exchanger Tube

Material: 304L, 1.4306, S30403, 1.4307;

Get Quote

TP304L 25.4*2.11mm U Bend Stainless Steel Heat Exchanger Tube

Heat Exchanger Tube:

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry, water heater industry, air-conditioning industry, etc. This kind of seamless tube has a very important position in our all products.

Heat Exchanger Tube Chemical Composition——Basic Raw Materials:

ASTM/UNS | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cr | Ni | Mo | Ti |

TP304/S30400 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | ||

TP304L/S30403 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-13.0 | ||

TP304H/S30409 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 | ||

TP316/S31600 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

TP316L/S31603 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

TP316Ti/S31635 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

TP321/S32100 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

TP317L/S31703 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |

TP347H/S34709 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 | ||

TP309S/S30908 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

TP310S/S31008 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | 0.75 |

Heat Exchanger Tube Application:

a) Petroleum, Chemical enterprise, superheater of boiler and heat exchanger

b) High temperature-resistant transmission fluid pipe in power station

c) Ship with pressure pipe

d) Exhaust purification device

e) Construction and ornament

f) solar industry, military, semiconductor, etc

Heat Exchanger Tube Process :

1 . We use Cold Drawn technology to produce U bend tube

2. U bend tubes produce will accordance to customer's drawings

3 . To avoid oxidation, inert gas (Argon) is passed through tubes ID at the required flow rate

4 . The radius is checked for its OD and wall thinning with the recommended specification

5 . We'll choose three different positions or as customers require to make sure tubes quality. We'll do physical properties and micro-structure test

6 . Visual inspection for waviness and cracks is done with Dye Penetrant Test

7 . Each tube is then hydro tested at the recommended pressure to check for leakage

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

3 / 4 Inch S32750 / S32760 Small Diameter Duplex Steel Tube With Rapid Cooling

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc Outer Diameter: 3.18mm - 101.6mm Wall Thickness: 0.5mm - 20mm Length: as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5etc. Application a) Petroleum b) Chemical indust......

ASTM A789 1 / 2 Inch S31803 1.4462 Duplex Stainless Steel Tube With High Tensile Strength

Duplex Seamless tube is a special type of stainless steel tube that consists of two crystalline organizations, austenite and ferrite. This tube has excellent corrosion resistance and high strength, combining the superior corrosion resistance of austenitic stainless steel with the high strength chara......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語