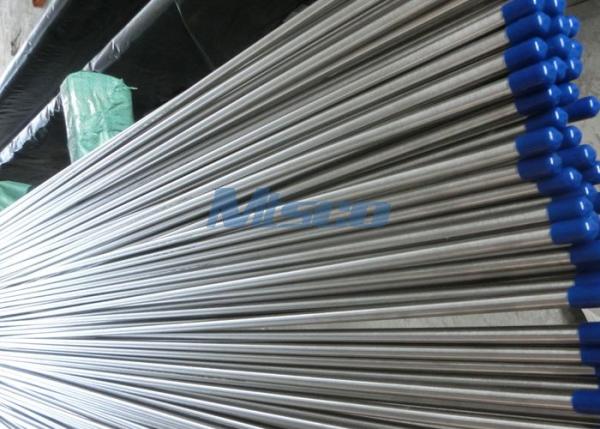

ASTM B622 Nickel Alloy Tube Alloy G-35 Seamless Tube For Chemical Environments

SSNAT34

Price: From $42000-70000USD/TON

Material: Alloy G-35, UNS N06035;

Get Quote

ASTM B622 Nickel Alloy Tube Alloy G-35 / UNS N06035 Seamless Tube For Chemical Environments

Item | Description |

Material Grade | UNS N06200,UNS N06035, UNS N06030, UNS N06635, UNS N06230, UNS R30556 |

Outer Diameter | 3.18mm-101.6mm |

Wall Thickness | 0.5mm-20mm |

Length | Normally fixed length 6m, can as per customer's requirement |

Standard | ASTM B622, ASTM B 619; ASTM B626; ASTM B444 etc |

Process Method | Cold Drawn or Cold Rolled |

Application | Chemical processing involving phosphoric acid, sulfuric acid and nitric acid; nuclear fuel reprocessing; nuclear waste processing; pickling operations; petrochemical; fertilizer manufacture; pesticide manufacture; and gold ore extraction. |

Advantages | a) Maintains excellent ductility during transient exposures to intermediate temperatures; |

| b) Excellent resistance to pitting and stress-corrosion cracking | |

| c) Excellent resistance to knife-line and heat-affected zone attack | |

Price Item | FOB, CFR, CIF or as negotiation |

Payment | T/T, LC or as negotiation |

Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

Package | Iron case; woven bag or as per customer’s requirement |

Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

Test | NTD(Ultrasonic test, Eddy Current test) |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | |

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | |

| Chemical Analysis(Photoelectric Emission Spectroscopic) | |

Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Alloy G-35 Chemical composition:

| % | Ni | Cr | Fe | Mo | W | Co | C | Mn | Si | P | S | Cu | Nb+Ta |

| min | balance | 28.0 | 13.0 | 4.0 | 1.5 | - | - | - | - | - | - | 1.0 | 0.30 |

| max | 31.5 | 17.0 | 6.0 | 4.0 | 5.0 | 0.030 | 1.5 | 0.80 | 0.040 | 0.020 | 2.4 | 1.50 |

Features:

Alloy G-35 / UNS N06035 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and sulfuric acids. It resists the formation of grain boundary precipitates in the heat-affected zone, making it suitable for use in most chemical process environments in the as-welded condition.

Applications:

Chemical processing involving phosphoric acid, sulfuric acid and nitric acid; nuclear fuel reprocessing; nuclear waste processing; pickling operations; petrochemical; fertilizer manufacture; pesticide manufacture; and gold ore extraction.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

10 / 12 / 14SWG Precision Stainless Steel Seamless Tube With Cold Rolled For Medical Industry

MTSCO has the most advanced technology — The floating plug drawing technology which are used in Korea , and equipped with the most environmentally process — Bright annealing process . So our bright annealed precision tube produce technology make us can produce 300 tons high precision tubes every m......

ASTM B168 / B906 Alloy 601 / N06601 Nickel Allloy Thick Plate With Cold Rolled

1. Grade : UNS N06601, N07718, N10276, UNS N06455, UNS N10001, UNS N10665, UNS N10675, UNS N06022,N08800, N08825, N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B333; ASTM B575; ASTM B168; ASTM B443; ASTM B670 etc. 4. Technology : Cold Drawn / Cold Rolled Features: A......

ASTM B444 / B829 Alloy 625 Nickel Alloy Seamless Tube

1. Grade : Alloy625 / N06625 , Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 , Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm 3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm 4 . Length : As cus......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語